Serviceability testing of gas pipelines:

Quick and successful measurement

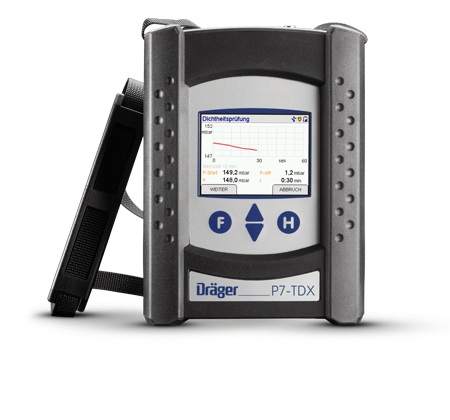

With the serviceability test of gas pipelines or leak rate determination, existing gas pipelines with operating pressures of up to 100 mbar are safety and easily tested. You can carry out the serviceability test with a leak rate measurement device fully automatically at operating pressure. (With the Dräger P7-TD and Dräger P7-TDX, leak rate measurement without removing the gas meter and without having to pump additional gas or air is possible).

Every operator of a gas system is required to have the serviceability of gas pipelines inspected by an expert every 12 years. The test method is delineated in DVGW Bulletin G5952. For leak rate measurement, the Dräger P7-TD or Dräger P7-TDX are the ideal measurement instruments.

How is the serviceability test of gas pipelines carried out safely?

This is the first step: The pressure and leak testing device is connected to the pipeline for leak rate determination, e.g., on the test supports of the gas fitting. After a short period of stabilisation, the main cock is attached to the gas pipeline.

Then, serviceability testing begins. The leak rate of the gas pipeline is measured fully automatically while simultaneously the results are shown in the display. After successful measurement, you can immediately read off the leak rate of the serviceability test.

Additionally, in the context of serviceability testing, functionality and external condition of the gas system must be inspected - so-called visual testing according to TRGI.

Serviceability is distributed as follows:

- Unlimited serviceability: Leak rate <1 litre/hour and no visible defects

- Reduced serviceability: Leak rate >= 1 and <5 litres/hour

- No serviceability: Leak rate >= 5 litres/hour

The serviceability testing of gas pipelines is carried out by the sanitary, heating, and air conditioning professionals such as heating engineers and installers, and in industry.

TRGI stands for the ‘Technical Regulation for Gas Installation’ (Technische Regel für Gasinstallation) and is the most important datasheet for gas installations in buildings. It contains regulations for planning, production, modification and operation of gas installations with an operating pressure of up to 1 bar in buildings and on property. Significant content for measurement technology Chapter V and Section 13 includes three different tests (lines up to 100 mbar operating pressure):

- Load test (pre-test)

- Leak detection (main testing)

- Serviceability testing (leak rate measurement)

Serviceability testing is required every 12 years for operating pipeline systems with operating pressures of up to 100 mbar. Additionally, an annual visual inspection must be carried out of the pipeline system on wall ducts.

TRF stands for ‘Technical Regulations for Liquefied Gas’ in German, comprising rules and requirements for the marketing, establishment and operation of liquefied gas systems based on applicable regulations and standards. The TRF establishes a pressure test and leak test that must be carried out immediately before commissioning. Then, a recurring leak test for lines that are in operation is prescribed.

The DIN 806-4 is a European standard that regulates the testing of drinking water systems. It contains recommendations and requirements for the installation of drinking water systems inside buildings and the installation of pipelines outside buildings. It can be used on new installations, overhauls and repairs.

The ZVSHK datasheet focuses on leak detection of drinking water systems with compressed air, inert gas or water. There are three variants for leak detection with water, depending on the active ingredient. The modified method can be used for all substances and combinations of substances. For leak detection with water, test method B as per DIN EN 806-4 applies. The test time is extended according to the current datasheet so that even the smallest leaks can be detected during the leak test. Additionally, the duration of the test method is expanded with compressed air or inert gases.

DIN EN 1610 is the basic standard for the installation and testing of sewage pipelines and tunnels. In the testing of sewage pipelines with air, the test duration depends on the test method, the substance and the pipe diameter.

Worksheet G 459/I addresses the planning and design of house connections for gas supply up to 4 bar operating pressure. Pressure testing must be carried out before commissioning according to DVGW Worksheet G 469.

Pressure testing for house connection pipelines can be carried out with the Dräger P7-TDX or the Dräger P7-TD.